Refractory

Refractories are lining materials used to protect equipment during metal melting and to provide a direction of flow to the molten metal. They are in direct contact with the molten material and thus must be robust and resistant enough to withstand high temperatures.

As Central India’s largest steel company†, Ramsons understood the industry’s requirements and began manufacturing refractory products such as Refractory bricks, Tundish boards, Garseal, Sleeves, and many others. Since we understand the need for the best quality of refractories required for steel, we produce it.

Our Products

Garseal Compounds

Tundish Boards

Refractory Shapes

High Alumina Bricks

Garseal Compounds

Garseal Compounds are essential binding pastes offered by Ramsons to properly seal Tundish Boards.

Tundish Boards

Playing a critical role in the steelmaking process, Ramsons’ Tundish Boards made using silica offer high-temperature resistance, thermal stability, chemical resistance as well as features insulating properties to be used as the lining material in tundishes in Ramsons’ steel mills and foundries.

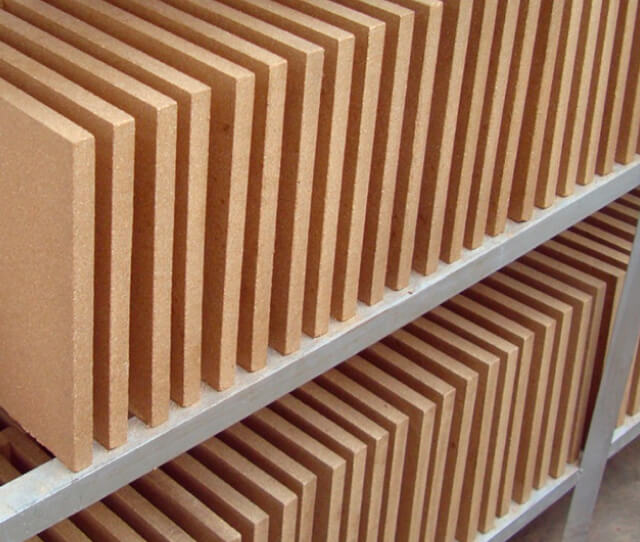

Refractory Shapes

Refractory products can have various designs to cater to different kinds of lining requirements. From ladle lining to kiln walls, Ramsons’ wide variety of expertly crafted shapes are manufactured to withstand extreme temperatures and chemical exposure, thus optimising performance and providing longevity in steel manufacturing process .

High Alumina Bricks

Primarily composed of alumina (Al2O3), Ramsons’ High Alumina Bricks offer exceptional resistance to thermal and chemical stresses. Additionally, features, including corrosion and wear resistance, high bulk density, and low iron content makes our High Alumina Bricks ideal for your industrial applications.